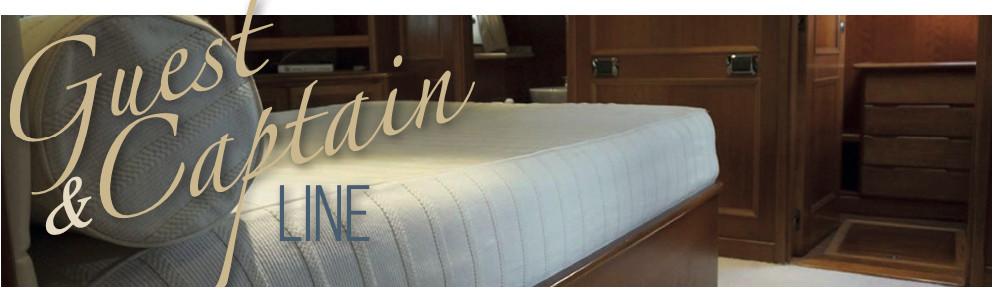

Mattresses for Home, Hotel and Ship.

Hotel supplies

Ship supplies

Yacht

Yacht

Cruise

Commercial ships

MATERIALS AND TREATMENTS

Science, technology, chemistry, and tradition work together with Mother Nature

100% MADE IN ITALY

Excellent air flow

A next-generation polyurethane foam material that features an open cellular structure which ensures air flow and optimal heat and moisture dispersion. Excellent performance in terms of durability and resistance to wear.

Non-deformable and cool

Watergel® is a high-density polyurethane gel foam. The special properties of this padding material are extreme flexibility, virtual non-deformability, exceptional freshness, and outstanding air flow.

Precious natural fibers

This padding material features fine natural fibers such as cashmere, silk, camel, linen, silver, PCM, PLA, soy, bamboo. It is flame retardant, exceptionally elastic, resistant to weight and pressure, lightweight and comfortable.

Valuable softness

A fabric created with a cashmere and cotton yarn blend. Top quality primary materials to provide maximum comfort and absolute softness to the touch. The high quality of these natural materials also guarantees long lasting durability of the inner mattress system.

Comfort and durability

A collection of foam mattress padding with varying density, firmness, and pressure values. The common feature is the balance between firmness, elasticity, and air circulation, which makes this material very comfortable and durable.

The color of good sleep

MalvaFoam® adds mallow extract to a highly resilient polyurethane foam. The padding is characterized by its elasticity and exceptional comfort, but also by the color and scent of this herb, whose soothing and relaxing properties have been known since ancient times.

Approved by Mother Earth

A unique padding material created from the perfect combination of Waterlily™ technology and essential oils, and soy-based raw materials. The result is a natural product that provides exceptional comfort, breathability, strength, and elasticity.

Rest responsibly

Biogreen is the perfect combination of polyurethane foam and essential oils obtained from linen, wool, and coconut. It guarantees maximum comfort, total non-deformability, and genuine rest. Biogreen chemistry and renewable resources for environmentally friendly relaxation and rest.

As soft as a cloud

Polyurethane foam mattress padding that features extreme softness, excellent elasticity, and the ability to always return to its original shape.

Super elasticity

This padding material combines a slightly higher degree of firmness with excellent bounce and super elasticity.

Fireproof comfort

Elasticity, non-deformability, and comfort are the characteristics of our Shaping padding material. Its added value lies in its very high resistance to fire, certified in compliance with the following standards: FAR 25853 – CSE.RF4/83 – CLASS 1 IM.

Beauty treatment

Fabrics treated with Aloe Vera are a real boon for sleepers, thanks to the countless therapeutic properties offered by this plant belonging to the Aloeceae family. Its gradual release hydrates and soothes the skin, transforming sleep into an everyday well-being experience.

Night-time breathability

The Air System fabric is extremely breathable. Thanks to its structure, which favors the constant exchange of heat and humidity, the bed temperature is always optimal, ensuring good quality of sleep and durability of the mattress and its accessories.

Teflon

Our TeflonTM fabric protection allows fabrics to stay cleaner, brighter, and fresher and is perfect for mattresses. This popular treatment does not alter the look, feel or breathability of fabrics. With the TeflonTM fabric protector, you’ll find that with a little cleaning, even the toughest stains disappear easily.

SPRING TECHNOLOGIES

The innovative spring system that takes care of your dreams

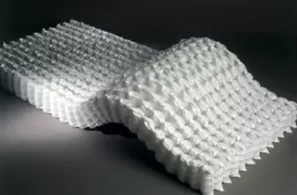

AIR SUSPENSION

“AIR SUSPENSION” the new dimension of rest. Structure microsprings active (example 1.500 coils single – 3.000 coils double) with independent movement that respond in a timely manner to the pressure exerted by the human body, thus managing to get really great anatomical and ergonomic solutions. The micro springs, which are individually pocketed and joined together by connecting thermically welded points, guarantee the independence and the noiseless movement of each spring, therefore allowing the body to fit itself to every single position it takes while sleeping: in fact springs work independently and while doing this, they wind round the spine and help to balance the pressures.

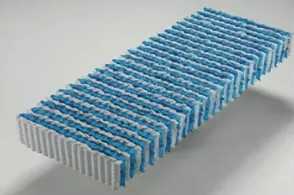

MICROPOCKET

Structure constitued of a high number of tempered microsprings (example 750 coils single – 1.500 coils double) inserted in proper pockets made of fabric, suitable not to generate moulds and other pathogenous agents, caused from the extravasation of dampness sent out from the body in the sleep. The microsprings, which are individually pocketed and joined together by connecting thermically welded points, guarantee the independence and the noiseless movement of each spring, therefore allowing the body to fit itself to every single position it takes while sleeping: in fact springs work independently and while doing this, they wind round the spine and help to balance the pressures.

Structure constitued of a high number of tempered springs inserted in proper pockets made of fabric, suitable not to generate moulds and other pathogenous agents, caused from the extravasation of dampness sent out from the body in the sleep. The springs, which are individually pocketed and joined together by connecting thermically welded points, guarantee the indipendence and the noiseless movement of each spring, therefore allowing the body to fit itself to every single position it takes while sleeping: in fact springs work independently and while doing this, they wind round the spine and help to balance the pressures. Such an indipendent innerspring can be used on motion nets, allowing them to bend without causing any damages.

BONNEL

Traditional tied biconical springs’ system in which the springs are automatically connected with a coiled steel wire. According to the number of springs inserted (93 springs/m² to 136 springs/m²) and to the diameter of wire used for construction of the individual spring (2.00-2.20-2.40mm) and different degree of rigidity can be obtained. The height of springs varies from a minimum of 7 cm to a maximum of 14 cm, including the 11 cm intermediate size. This structure can be further on reinforced with the application of a perimetral steel frame.